Sewing machine needle

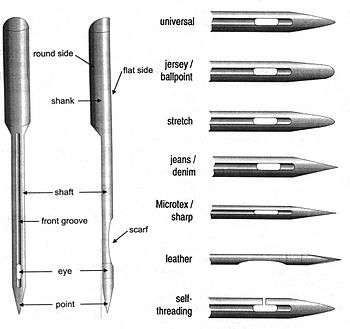

A sewing machine needle is a specialized needle for use in a sewing machine. A sewing machine needle consists of:[1]

- shank - clamped by the sewing machine's needle holder

- shoulder - where the thick shank tapers down to the shaft

- shaft - a length suitable for driving the eye and thread through the material and down to the bobbin

- groove - cut in the back of the shaft to release the thread into a loop that aids the hook or shuttle to pick up the thread

- scarf - provides extra room for the hook or shuttle to pass close by

- eye - carries the thread

- point - penetrates the material by either parting the threads or cutting a hole in the fabric

Construction

The majority of sewing machine needles are made of various grades of hardened chrome-plated steel, though certain specialty needles are coated with titanium rather than chrome.

Size codes

More than twelve conventions exist for numbering the sizes of sewing machine needles, though only two remain in common use: the American (established and propagated by Singer) and the European (also called the "number metric" or "NM"). The European designation, established in 1942, is considered the uniform fixed size and corresponds to the diameter of the needle in hundredths of a millimeter at a non-reinforced point above the scarf. The following chart gives a comparison of the two systems. In both cases, a larger number corresponds to a larger, heavier needle.

| American | European |

|---|---|

| 8 | 60 |

| 9 | 65 |

| 10 | 70 |

| 11 | 75 |

| 12 | 80 |

| 14 | 90 |

| 16 | 100 |

| 18 | 110 |

| 19 | 120 |

| 20 | 125 |

| 21 | 130 |

The size of a given needle is often indicated with a pair of these numbers, e.g., "14/90" or "90/14" (the order of the numbers has no significance).

Types

Most currently manufactured needles are designated according to "type", and fall into the following categories:

| Type | Description |

|---|---|

| Universal | Intended as an all-purpose needle, preferred for woven fabrics where a sharper needle could ruin the fabric. Similar to a ballpoint needle but tapered to allow the needle to slip through without producing a run. |

| Embroidery | These needles come with an extra large eye and a specially shaped scarf to prevent embroidery thread from shredding. |

| Ballpoint | Similar to a universal needle but has rounded edges and is not tapered the same way. Intended for closely knit fabrics where the rounded tip will push the weave out of the way rather than cut through it. |

| Jeans/ Denim | Intended for tightly woven cottons such as canvas. Has a strong, sharp point and very slender eye. |

| Wing | Needle has distinct "wings" on either side of the eye which hold the fabric open. Often used on hems and borders, and for decorative finishing. A larger size needle will leave a larger hole in the final piece of sewn fabric. |

| Leather | These have a distinct triangular point to help the needle make a large, clean hole in non-woven materials like vinyl. |

| Metallic | Similar to an embroidery needle with a large eye and extra long scarf, but also includes a Teflon coating to the eye so that metallic threads will not shred when used. |

| Quilting | Designed with an extra strong shaft and with a tapered point to penetrate multiple layers of woven fabrics without breaking and without shredding either the thread or the fabric being sewn. |

| Serger/ Industrial | These needles can only be used in serger and overlocking machines. |

| Microtex/ Sharps | More slender and sharper than the universal needle. Suitable for fine woven fabrics, but also compatible for quilting and appliqué. |

| Stretch | These needles are intended for use on fabrics with a significant amount of Spandex or similar fabric content. Rounded tip and specialized scarf and eye to prevent skipping. |

| Topstitching | These have exceptionally sharp points and a very large eye to accommodate thick decorative topstitching threads. Very similar to the leather needle. |

| Twin/ Triple | Needles set in pairs or in groups of three on a single shaft designed to sew multiple, usually decorative, threads at once. These require specialized machinery to accommodate the extra needles, as well as multiple thread feeds. The twin or triple designation is usually accompanied by another needle type specification such as "stretch" or "denim", etc. |

Singer number and color codes

Singer colors and numbers its needles with the following system of codes to indicate the needle point type and shaft size:

| code and shank color | Point type |

|---|---|

| 2000 - uncolored | chromium-coated regular point, for high-speed embroidery stitching |

| 2020 - red | regular point, for woven fabrics (most common Singer needle type) |

| 2022, 2053, 2054 - uncolored | overlock needles, only for overlocking machines |

| 2044 - uncolored | embroidery needle |

| 2045 - yellow | ball point, for knits |

| 2026 - blue | heavy-duty point, for denims |

| 2032 - brown | chisel or wedge point, for leathers |

| 2025 - uncolored | twin needles |

| 2040 - uncolored | hemstitch or wing-needle, for "heirloom" or decorative sewing, best on woven cottons and linens |

| Shoulder color | Shaft size |

|---|---|

| green | 9 |

| orange | 11 |

| blue | 14 |

| purple | 16 |

| gray | 18 |

Kenmore color codes

Kenmore colors its needles with a different system of color codes which indicate the needle's size:

| Shank color | Shaft size | Shaft size (Europe) |

|---|---|---|

| blue | 11 | 75 |

| orange | 12 | 80 |

| red | 14 | 90 |

| purple | 16 | 100 |

| green | 18 | 110 |

Schmetz Color Codes

The colored band on some types of Schmetz needles indicates the needle type.[2]

| Shank color | Type |

|---|---|

| yellow | Stretch |

| blue | Jeans |

| green | Quilting |

| red | Embroidery |

| purple | Microtex (sharp) |

References

- ↑ Lydia Morgan (November 6, 2008). "Machine-needle know-how". Threads Magazine. No. 94. pp. 59–61.

- ↑ Schmetz Needle Chart

and needle parts