Tappet

A tappet is a projection that imparts a linear motion to some other component within a mechanism.

Beam engines

.jpg)

The term is first recorded as part of the valve gear of Thomas Newcomen's atmospheric beam engine, a precursor to the steam engine. The first Newcomen engines had manually worked valves, but within a few years, by 1715, this repetitive task had been automated. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets pressed against long levers or 'horns' attached to the engine's valves, working the cycle of steam and injection water valves to operate the engine.[1] This operation by tappets on a plug rod continued into the early twentieth century with the Cornish engine.[2]

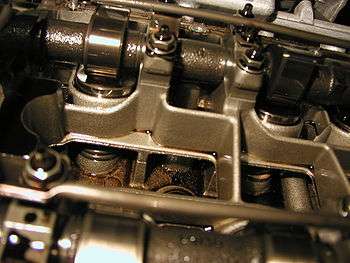

Internal combustion engines

The term tappet is widely used in relation to internal combustion engines, but imprecisely. It is most commonly encountered as a maintenance task for overhead valve engines, that of 'adjusting the tappets'. This operation adjusts the overall clearance in the valve actuation system: typically 20 thousandths of an inch (0.5 mm). The name arises because it is the clearance of the tappets that is being adjusted, even though the adjustment is not made to the tappets themselves.

Strictly speaking, the tappet, also termed a cam follower,[3][4] or lifter,[5] is that part that runs on the camshaft and is made to move vertically by the action of the rotating cam. In an overhead valve engine, this tappet is fitted low down in the engine block. From there it drives a long thin pushrod, up to the top of the engine, above the cylinder head. Here the rockers, arranged on a rocker shaft beneath the rocker cover, reverse the direction of the valve movement to press the valves downwards to open them.[6]

Early tappets had rollers to reduce wear from the rotating camshaft,[4] but it was found that the roller pivots wore even faster and also that the small radius of the rollers also tended to accelerate wear on the expensive camshaft. Tappets then developed plain flat ends, although these were slightly radiused as 'mushroom' tappets as a perfectly flat end led to 'slamming' against a steep camshaft face.

To reduce wear from the rotating camshaft, the tappets were usually circular and allowed, or even encouraged, to rotate. This avoided grooves developing from the same point always running on the same point of the camshaft. In a few engines, particularly small V8 engines with little space, the tappets were small and non-rotating.[note 1]

Adjustment

This long and widely used engine arrangement was adjusted by turning a screw set in the end of the rocker that pressed on the end of the pushrod. This adjustment was made by rotating the engine until the cam was at its lowest point, giving the widest gap, then adjusting the rocker until this gap was at the correct spacing, as measured with the use of a feeler gauge.

Mis-adjusted tappets can give rise to an audible 'tappet rattle' from the rocker cover, if the valve clearances are excessive. Over-tight clearances may, even worse, lead to bent pushrods. The adjusting screw was locked by a locknut. If the screw became loose, the adjustment would also work loose. Such a simple matter as a loose tappet locknut even led to an engine fire, then the aircraft crash that led to the death of WWII radar expert Alan Blumlein.[7]

Some mass-market car engines from the 1960s[note 2] replaced the rocker-end adjustment screw with a non-adjustable rocker pivoted on a central stud with a hemispherical nut. Tappet adjustment was made by moving the pivot nut up and down. Some of these designs also required the tappet clearance to be set with the engine running.[note 3] As this rapidly wore out feeler gauges, long rolls of disposable feeler strip were needed instead.

Hydraulic tappets

Hydraulic tappets are tappets that contain a small hydraulic piston, pressurised by the engine's lubricating oil supply.[4][8] Although the piston does not move appreciably or frequently, it acts as a hydraulic spring that automatically adjusts the tappet clearance according to the oil pressure. This makes the valve actuation self-adjusting and there is no need to adjust the rockers. Hydraulic tappets depend on a supply of clean oil at the appropriate pressure. When starting a cold engine, with low oil pressure, hydraulic tappets are often noisy for a few seconds, until they position themselves correctly.

Sidevalve engines

.jpg)

The earlier sidevalve engine had a similar arrangement, but simpler. As the valves were mounted at the sides of the cylinder and faced upwards, the camshaft could be placed directly beneath them and there was no need for a rocker. With lower cylinder blocks, the tappets could drive the valves directly without needing even a push rod.[4][9]

Sidevalve engines also required their tappets adjusting, and in this case it was the tappets themselves that were adjusted directly. Small access plates were provided on the sides of the cylinder block, giving access to the gap between the valves and tappets. Some tappets had a threaded adjuster, but simpler engines could be adjusted by grinding down the ends of the valve stem directly. As the adjustment gap need only be expanded over the engine's working life (re-grinding valves into their valve seats during de-coking makes them sit lower, thus closing up the tappet gap), adjustment by removing metal was acceptable. Care was obviously needed, to not remove too much. Eventually the valves would be replaced entirely, a relatively common operation for engines of this era.

Overhead cam engines

.jpg)

Overhead cam engines were first developed as high performance aircraft and racing engines, with the camshafts mounted directly over the valves and driving them through a simple bucket tappet. To give the best valve position for gasflow through a crossflow cylinder head, valves were usually mounted in two rows and with two separate camshafts. These bucket tappets were usually adjusted by a small shim, either above or below the tappet. Shims were made in a range of standard thicknesses and a mechanic would swap them to change the tappet gap. The engine would first be assembled with a default shim of known thickness, then the gap measured. A set of different shims would then be installed, each one chosen according to the change needed from the measured gap to the ideal gap. The gaps would then be measured again, in case of mistakes and also in case the cam position had shifted slightly. As the camshaft had to be removed to change the shims, this was an extremely time consuming operation, especially as the precise height of the camshaft above the cylinder head could change, depending on how carefully it was re-installed.

A much-improved system placed the shims above the tappet. This allowed each shim to be changed without removing either the tappet or camshaft, usually by pressing the tappet and valve down against the valve spring with a lever tool and removing the shim with tweezers. A difficulty with this system is that the rubbing surface of the tappet becomes the surface of the shim, which is a difficult problem of mass-production metallurgy. The first mass production engine to use this system was the Fiat twin-cam engine of the early 1960s, followed by engines from Volvo and the water-cooled Volkswagens.[10]

Overhead rockers

.jpg)

The development of more efficient OHC mass-production car engines in the 1960s, combining overhead crossflow valves with the low cost of a single camshaft encouraged engines with overhead rockers, directly beneath a single overhead camshaft.[note 4] These rockers combined the function of sliding tappet, rocker and adjustment device. Adjustment was usually by a threaded pivot stud beneath the rocker. Linear sliding tappets became a problem for wear and demanded careful lubrication. Some engines, such as the Ford Pinto, developed a poor reputation for camshaft wear and encouraged aftermarket improvements to their lubrication systems.

Other uses

.jpg)

The term 'tappet' is also used, obscurely, as a component of valve systems for other machinery, particularly as part of a bash valve in pneumatic cylinders. Where a reciprocating action is produced, such as for a rock drill, the valve may be actuated by inertia or by the movement of the working piston. As the piston hammers back and forth, it impacts a small tappet, which in turn moves the air valve and so reverses the flow of air to the piston.[11]

Notes

- ↑ The Daimler 2.5l V8 was an example

- ↑ The Ford Transit V4, some GM small car engines

- ↑ GM engines

- ↑ The Ford Pinto engine is a good example of these, along with the Triumph Dolomite Sprint engine that became the first mass-production 16 valve engine, by using a clever arrangement of rockers and a single 8-lobe camshaft.

References

- ↑ The Newcomen Memorial Engine. Dartmouth, England: Newcomen Society.

- ↑ Woodall, Frank D. (1975). Steam Engines and Waterwheels. Moorland. pp. 31–34. ISBN 0903485354.

- ↑ Setright & Anatomy of the Motor Car, p. 33

- 1 2 3 4 Hillier, V.A.W. (1981). Fundamentals of Motor Vehicle Technology (4th ed.). Stanley Thornes. p. 44. ISBN 0-09-143161-1.

- ↑ http://www.thecarguys.net/valve_system_operation.pdf

- ↑ Setright, L. J. K. (1976). "Valve gear". In Ian Ward. Anatomy of the Motor Car. Orbis. pp. 29–36. ISBN 0-85613-230-6.

- ↑ Alexander, Robert Charles (1999). The Inventor of Stereo: The Life and Works of Alan Dower Blumlein. Focal Press. ISBN 0-240-51628-1.

- ↑ Setright & Anatomy of the Motor Car, p. 33

- ↑ Setright & Anatomy of the Motor Car, p. 34

- ↑ Setright & Anatomy of the Motor Car, p. 34

- ↑ Kennedy, Rankin (1912 edition of 1905 book.). The Book of Modern Engines and Power Generators. VI. London: Caxton. p. 162-166. Check date values in:

|date=(help)